Infrastructure

BAWA ENGINEERS

OUR MACHINE

CAPACITY

Machinery at Our Facility

| Type | Manufacturer | Travel Specifications (mm) | Company | Origin | Chuck Size | Quantity |

|---|---|---|---|---|---|---|

| CNC Machine | LOKESH | 400×150 | Make in Hyd. | INDIA | 08″-12″ | 02 |

| CNC Machine | LOKESH | 300×300 | Make in Hyd. | INDIA | 08″-12″ | 07 |

| CNC Machine | LOKESH | 400×300 | Make in Hyd. | INDIA | 08″-12″ | 01 |

| CNC Machine | LOKESH | 350×300 | Make in Hyd. | INDIA | 08″-12″ | 01 |

| CNC Machine | PRIDE | 350×300 | Make in Hyd. | INDIA | 08″-12″ | 01 |

| Total | 12 | |||||

| Type | Manufacturer | Travel Specifications (mm) | Company | Origin | Chuck Size | Quantity |

|---|---|---|---|---|---|---|

| VMC Machine with 4TH Axis | LOKESH | 800×400 | Make in Hyd. | INDIA | 10″-12″ | 03 |

| VMC Machine | LOKESH | 800×400 | Make in Hyd. | INDIA | 10″-12″ | 01 |

| VMC Machine | LOKESH | 1000×600 | Make in Hyd. | INDIA | 12″-14″ | 01 |

| Total | 05 | |||||

| Type | Manufacturer | Company | Origin | Travel Specifications (mm) | Chuck Size | Quantity |

|---|---|---|---|---|---|---|

| Lathe | DH Machine Tools | Make in Delhi. | INDIA | 1200×350 | 08″-12″ | 14 |

| Lathe | MK Machine Tools | Make in Maharashtra | INDIA | 1200×350 | 08″-16″ | 02 |

| Lathe | Lakshmi Machine Works Limited | Make in Tamil Nadu | INDIA | 1200×350 | 08″-16″ | 02 |

| Lathe | Kirloskar Machines | Make in Tamil Nadu | INDIA | 1800×350 | 08″-16″ | 01 |

| Colchester | – | Make in West Yorkshire | United Kingdom | 1800×350 | 08″-16″ | 01 |

| Total | 20 | |||||

| Type | Manufacturer | Company | Origin | Travel Specifications (mm) | Drilling Dia | Quantity |

|---|---|---|---|---|---|---|

| Column Drilling Machine | Siddhapura Machine Tools | Make in Gujarat | INDIA | 300 | 2000 RPM Upto 25 mm | 11 |

| Pillar Drilling Machine | WEBO | Make in Eislingen | Germany | 300 | 2500 RPM Upto 35 mm | 04 |

| Pillar Drilling Machine | EDELSTAAL | Make in Konya | Turkey | – | 2500 RPM Upto 35 mm | 01 |

| Radial Drilling Machine | SICMAT | Make in Brandizzo | Italy | – | 2500 RPM Upto 50 mm | 01 |

| Radial Drilling Machine | BOWES | Make in Fontanafredda | Italy | – | 2500 RPM Upto 50 mm | 01 |

| Radial Drilling Machine | CASER | Make in Rome | Italy | – | 2500 RPM Upto 50 mm | 01 |

| Radial Drilling Machine | RAMBOMA | Make in Eislingen | Germany | – | 2500 RPM Upto 50 mm | 01 |

| Radial Drilling Machine | BATLI BOI | Make in Maharashtra | INDIA | – | 2500 RPM Upto 50 mm | 01 |

| Total | 21 | |||||

| Type | Manufacturer | Company | Travel Specifications (mm) | Origin | Milling Chuck Dia | Quantity |

|---|---|---|---|---|---|---|

| Milling Machine | Siddhapura Machine Tools | Make in Gujarat | – | INDIA | 1500 RPM Upto 35 mm | 01 |

| Milling Machine | MISAL | Make in Punjab | – | INDIA | 2500 RPM Upto 35 mm | 01 |

| Milling Machine | HMT | Make in Bangalore | – | INDIA | 2500 RPM Upto 35 mm | 03 |

| Total | 05 | |||||

Machine Shapes

Machine Shop

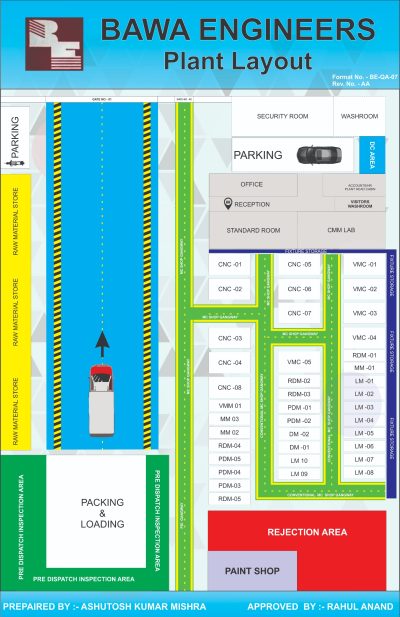

The Machine Shop is equipped with modern CNC (Computer Numerical Control) and VMC (Vertical Machining Centers) machines. This area is focused on precision machining, where raw materials are transformed into finished parts through milling, turning, drilling, and tapping operations. CNC machines allow for high accuracy and repeatability, making them essential for complex, high-precision parts.

Conventional Shop

The Conventional Shop houses traditional machinery such as lathes, milling machines, and grinders. Although less automated than CNC or VMC machines, conventional machines are versatile and are used for simpler operations or for working on parts that don’t require high precision. Skilled operators are essential in this area, as manual control allows for flexibility in small production runs or one-off components.

What We Have In Quality

CMM Room

The CMM Room is a dedicated space that houses Coordinate Measuring Machines (CMMs), which are essential for achieving high-precision measurements and ensuring dimensional accuracy of machined parts. CMMs use a probing system to detect exact coordinates on the part’s surface, which can then be compared to the CAD model or design specifications. This area is climate-controlled to prevent temperature fluctuations that could affect measurement accuracy, as even small changes can lead to measurement errors.

Standared Room

The Standard Room, sometimes referred to as the Metrology Lab, contains a variety of measurement instruments and gauges essential for quality control and calibration. This room holds calibrated equipment such as micrometers, calipers, dial indicators, height gauges, and other precision measuring tools, which are used to inspect parts and confirm that they meet the required specifications. Each instrument is calibrated regularly to traceable standards (like ISO, ASTM, or NIST) to ensure accuracy.

PDI Area

The Pre-Dispatch Inspection (PDI) Area is the last checkpoint before parts are shipped to customers. Here, quality inspectors conduct final inspections on dimensions, finishing, and functional aspects to ensure compliance with customer requirements. The PDI area ensures that only parts that meet high-quality standards are dispatched, maintaining customer satisfaction and trust.

What We Have

- WE HAVE 10 LATHE MACHINES

- WE HAVE 4 DRILLING MACHINES

- WE HAVE 5 RADIAL DRILL MACHINE

- WE HAVE 5 PILLER DRILL MACHINE

- WE HAVE 8 CNC MACHINES

- WE HAVE 5 4 AXIS VMC MACHINES

- WE HAVE 4 MILLING MACHINES

What We Have In M/Shapes

Machine Shop

The Machine Shop is equipped with modern CNC (Computer Numerical Control) and VMC (Vertical Machining Centers) machines. This area is focused on precision machining, where raw materials are transformed into finished parts through milling, turning, drilling, and tapping operations. CNC machines allow for high accuracy and repeatability, making them essential for complex, high-precision parts.

Conventional Shop

The Conventional Shop houses traditional machinery such as lathes, milling machines, and grinders. Although less automated than CNC or VMC machines, conventional machines are versatile and are used for simpler operations or for working on parts that don’t require high precision. Skilled operators are essential in this area, as manual control allows for flexibility in small production runs or one-off components.

What We Have In Quality

CMM Room

The CMM Room is a dedicated space that houses Coordinate Measuring Machines (CMMs), which are essential for achieving high-precision measurements and ensuring dimensional accuracy of machined parts. CMMs use a probing system to detect exact coordinates on the part’s surface, which can then be compared to the CAD model or design specifications. This area is climate-controlled to prevent temperature fluctuations that could affect measurement accuracy, as even small changes can lead to measurement errors.

Standared Room

The Standard Room, sometimes referred to as the Metrology Lab, contains a variety of measurement instruments and gauges essential for quality control and calibration. This room holds calibrated equipment such as micrometers, calipers, dial indicators, height gauges, and other precision measuring tools, which are used to inspect parts and confirm that they meet the required specifications. Each instrument is calibrated regularly to traceable standards (like ISO, ASTM, or NIST) to ensure accuracy.

PDI Area

The Pre-Dispatch Inspection (PDI) Area is the last checkpoint before parts are shipped to customers. Here, quality inspectors conduct final inspections on dimensions, finishing, and functional aspects to ensure compliance with customer requirements. The PDI area ensures that only parts that meet high-quality standards are dispatched, maintaining customer satisfaction and trust.

Machines List

| Type | Machine Name | Made In | Company | Specifications | Speciality |

|---|---|---|---|---|---|

| CNC-1 | LOKESH | INDIA | Made in Hyd. | 12″ 400X150 | High Precision and Accuracy |

| CNC-2 | LOKESH | INDIA | Made in Hyd. | 300X300 | Automated Tool Changing |

| CNC-3 | LOKESH | INDIA | Made in Hyd. | 300X300 | Versatile Material Compatibility |

| CNC-4 | LOKESH | INDIA | Made in Hyd. | 400X300 | High-Speed Operation |

| CNC-5 | LOKESH | INDIA | Made in Hyd. | 350X300 | Advanced Software Integration |

| CNC-6 | LOKESH | INDIA | Made in Hyd. | 400X150 | Minimal Operator Intervention |

| CNC-7 | LOKESH | INDIA | Made in Hyd. | 300X300 | Enhanced Safety Features |

| VMC Machine – 1 | LOKESH | INDIA | Made in Hyd. | 400×800 | Precision and Accuracy |

| VMC Machine – 2 | LOKESH | INDIA | Made in Hyd. | 600X1000 | Multi-Axis Capabilities |

| VMC Machine – 3 | LOKESH | INDIA | Made in Hyd. | 40000 | High-Speed Spindle |

| Radial Drill Machine – 1 | SICMAT | ITALY | – | Radial Arm Flexibility | High Precision |

| Radial Drill Machine – 2 | BOWES | ITALY | – | Versatile Drilling Capabilities | Ease of Handling Large Workpiece |

| Radial Drill Machine – 3 | CASER | ITALY | – | – | Adjustable Speed |

| Radial Drill Machine – 4 | RAMBOMA | Germany | – | – | High Precision |

| Radial Drill Machine – 5 | BATLI BOI | Mumbai | – | – | Ease of Handling Large Workpiece |

| Type | Machine Name | Made In | Company | Specifications | Speciality |

|---|---|---|---|---|---|

| Lathe-1 | Automatic | Coimbatore, India | Laxmi Machines | 12″ Turning | Facing |

| Lathe-2 | – | Coimbatore, India | Laxmi Machines | 500 Turning | Thread Cutting |

| Lathe-3 | – | Delhi | DH Machines | 16″ Drilling | – |

| Lathe-4 | – | Delhi | DH Machines | 12″ | – |

| Lathe-5 | Toolroom Turret | UK | COLCHSTER | 12″ | – |

| Lathe-6 | – | Delhi | MK Enterprises | 6″ Boring | Knurling |

| Lathe-7 | – | Delhi | MK Enterprises | 12″ Taper Turning | Grooving |

| Lathe-8 | – | Delhi | MK Enterprises | 12″ | – |

| Lathe-9 | – | Delhi | DH Machines | 84″ Turning | – |

| Drilling Machine-1 | – | Delhi | Sidhpura | 100-6858 | – |

| Piller Drill Machine-1 | – | Germany | WEBO | – | High Precision and Stability |

| Piller Drill Machine-2 | – | Germany | WEBO | – | Adjustable Depth Control |

| Piller Drill Machine-3 | – | US | Edelstaal | – | Variable Speed Settings |

| Milling Machine-1 | – | Punjab | MISAL | – | – |

| Milling Machine-2 | – | Bangalore | HMT | – | – |

Complete Machining and Manufacturing Solutions

5 VMC Machining Showcase

12 CNC Precision Showcase

10 Lathe Machining Showcase

5 RDM Precision Showcase ( Raidal Drilling Machine)

5 PDM Precision Showcase ( Pillar Drilling Machine)

3 Milling Machine

CNC & VMC SECTION

VMC SECTION 2

MILLING MACHINE SECTIONS

MACHINE SHOP

FINAL INSPECTION SECTIONS

STANDARD ROOM

CNC & VMC SECTION

CNC SECTION

VMC SECTION

VMC SECTION 2

MILLING MACHINE SECTION 1

MILLING MACHINE SECTION 2

MACHINE SHOP

LATHE MACHINE SECTION

FINAL INSPECTION SECTION 1

FINAL INSPECTION SECTION 2

STANDARD ROOM

STANDARD ROOM 2

CMM ROOM

MATERIAL STORAGE

OUR LATHE MACHINE

ABOUT

Our lathe machines are designed for precision and efficiency, making them ideal for a wide range of industrial applications. Built with robust materials and advanced technology, they offer high accuracy in operations such as turning, threading, drilling, and tapering. With user-friendly controls and versatile functionalities, our machines cater to both small-scale and large-scale production needs. Whether you require manual or automated lathes, we provide reliable solutions tailored to your requirements. Equipped with features like knurling and grooving capabilities, our lathe machines ensure consistent performance and durability. Perfect for machining operations, they deliver unmatched precision and adaptability across diverse materials.

ABOUT

Our drilling machines are engineered for precision, reliability, and efficiency in a variety of applications. Suitable for small to large-scale projects, these machines deliver accurate results in drilling operations. Built with sturdy materials and innovative technology, they ensure durability and consistent performance. Whether for metal, wood, or composite materials, our machines cater to diverse industrial needs. With adjustable speed settings and user-friendly designs, they provide maximum versatility and ease of use. From workshops to heavy-duty industries, our drilling machines are a trusted choice for delivering exceptional quality and productivity.

OUR DRILLING MACHINE

OUR RADIALDRILL MACHINE

ABOUT

Our radial drill machines are crafted to handle heavy-duty drilling tasks with precision and ease. Designed for versatility, they feature an adjustable radial arm, allowing operations on large and complex workpieces. These machines ensure high accuracy, stability, and power, making them ideal for industries requiring reliable performance. With advanced features like variable speed control and depth adjustment, they offer unmatched flexibility. Built for durability and efficiency, our radial drill machines are suitable for drilling, boring, and tapping operations, making them indispensable tools for modern machining and fabrication needs.

ABOUT

Our piller drill machines are designed for stability, precision, and power, making them ideal for heavy-duty drilling tasks. These machines feature a robust column structure that ensures vibration-free operations, even during intense workloads. With adjustable depth control and variable speed settings, they provide flexibility for a range of applications. Perfect for metalworking, woodworking, and industrial fabrication, our piller drill machines deliver consistent results and long-lasting durability, meeting the needs of modern industries.

OUR PILLER DRILL MACHINE

OUR VMC MACHINE

ABOUT

Our Vertical Machining Center (VMC) machines are engineered for high precision and efficiency in complex machining tasks. Equipped with multi-axis capabilities and high-speed spindles, they offer exceptional accuracy and surface finishes. With automated tool-changing systems and integrated coolant mechanisms, our VMC machines streamline operations for enhanced productivity. Perfect for industries requiring intricate designs and high-quality machining, these machines provide reliability, versatility, and superior performance.

OUR CNC MACHINE

ABOUT

Our CNC machines bring automation, accuracy, and repeatability to your machining processes. Designed to handle a wide range of materials, they are equipped with advanced software integration for precise control and customization. With features like automated tool changers, high-speed operation, and enhanced safety systems, our CNC machines ensure consistent quality and efficiency. From prototyping to large-scale production, they deliver unmatched versatility for various industrial applications.

ABOUT

Our milling machines are the perfect solution for precision cutting, shaping, and drilling tasks. Designed for durability and accuracy, they are ideal for machining complex parts with ease. With robust construction and advanced features like variable speed control and multi-axis capabilities, our milling machines cater to diverse industrial needs. Whether for prototyping or production, they provide consistent performance and adaptability across materials, ensuring high-quality results every time.

OUR MILLING MACHINE